जुन . 13, 2024 09:13

Back to list

Polyester fibre panel can be replaced with Synthetic fabric composite sheet.

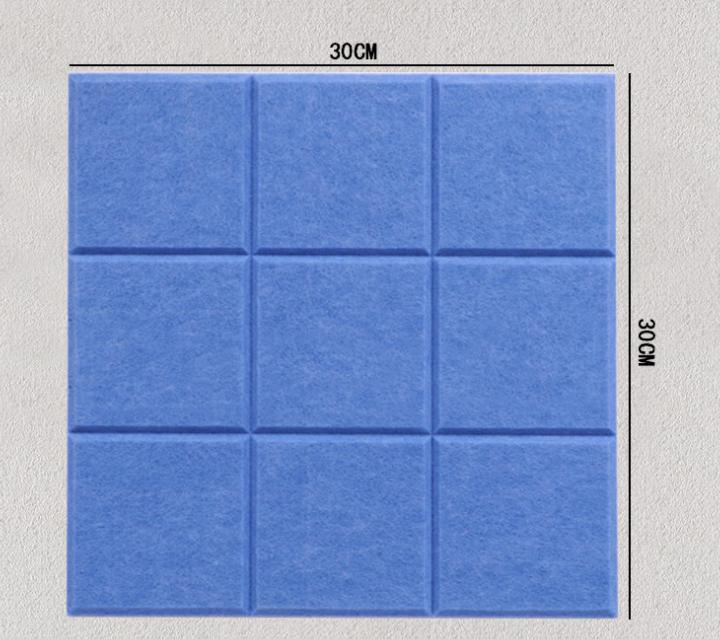

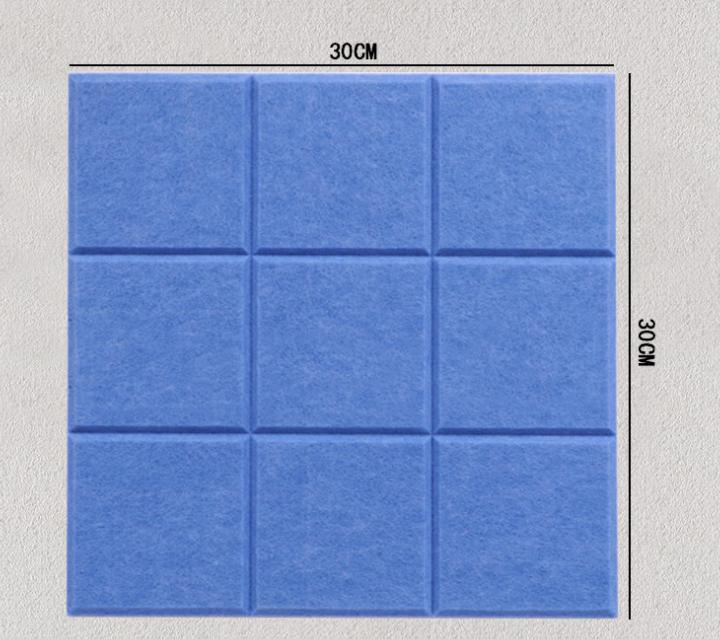

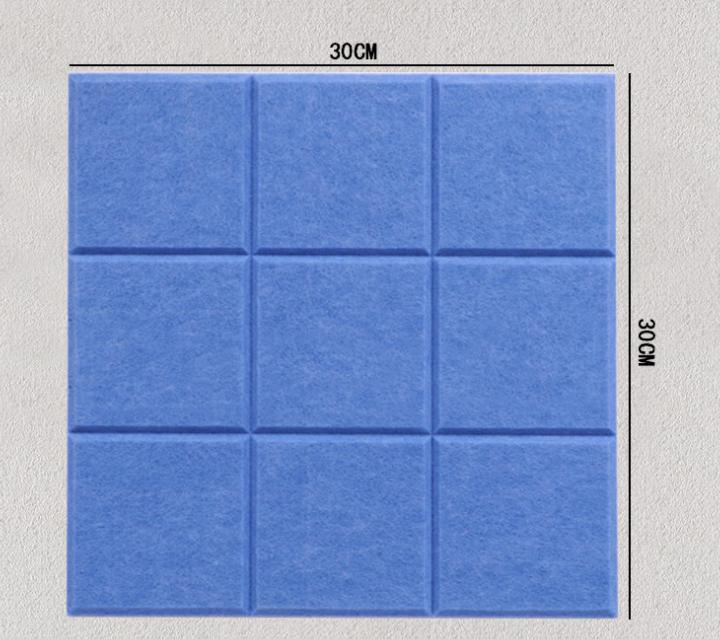

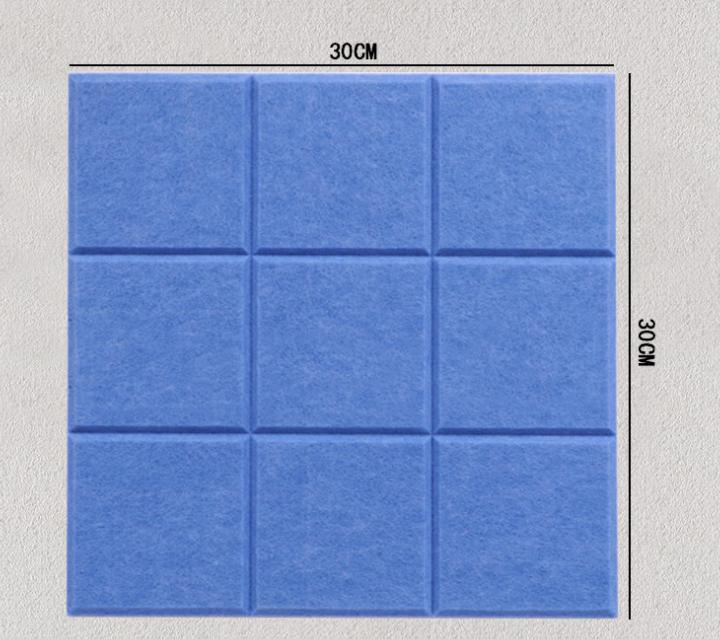

Understanding Polyester Fibre Panels A Comprehensive Overview

Polyester fibre panels have emerged as a popular choice in various industries due to their exceptional properties and versatile applications. These panels are primarily composed of polyester fibres, which are synthetic fibres derived from coal, air, water, and petroleum. The percentage of polyester in these panels can vary depending on the intended use and desired characteristics.

The core strength of polyester fibre panels lies in their inherent durability. With high tensile strength and resistance to stretching, they can withstand considerable stress without deforming or breaking. This makes them ideal for structural applications where strength and stability are crucial, such as in construction and engineering projects.

Moreover, polyester fibre panels exhibit excellent resistance to moisture, fading, and shrinking. They do not absorb water easily, which prevents swelling or distortion, even in humid conditions. This characteristic renders them suitable for outdoor applications, including roofing, cladding, and signage.

In the realm of acoustics, polyester fibre panels have found significant usage. Their sound-absorbing capabilities make them effective in noise reduction, enhancing the acoustic environment in auditoriums, studios, and office spaces. The fibre structure allows for the dissipation of sound waves, contributing to a more pleasant and quieter atmosphere.

Additionally, polyester fibre panels offer thermal insulation, helping maintain consistent indoor temperatures

Additionally, polyester fibre panels offer thermal insulation, helping maintain consistent indoor temperatures Additionally, polyester fibre panels offer thermal insulation, helping maintain consistent indoor temperatures

Additionally, polyester fibre panels offer thermal insulation, helping maintain consistent indoor temperatures

Additionally, polyester fibre panels offer thermal insulation, helping maintain consistent indoor temperatures

Additionally, polyester fibre panels offer thermal insulation, helping maintain consistent indoor temperatures polyester fibre panel. This property is beneficial in energy-efficient building designs, reducing heating and cooling costs. Furthermore, their non-flammable nature adds an extra layer of safety, particularly in fire-sensitive areas.

The manufacturing process of polyester fibre panels involves a combination of compression and bonding techniques. Fibres are first spun and then bonded together to form a solid, dense panel. This process ensures that the panels remain lightweight yet robust, making them easy to handle and install.

Furthermore, polyester fibre panels are environmentally friendly. Many manufacturers utilise recycled polyester fibres, contributing to waste reduction and sustainability efforts. Their long lifespan and recyclability further enhance their eco-friendly credentials.

In conclusion, polyester fibre panels, with their blend of strength, resilience, and versatility, have carved a niche in numerous sectors. Whether it's construction for their durability, acoustics for their sound absorption, or energy efficiency for their insulation, these panels continue to demonstrate their worth. As technology advances, we can expect polyester fibre panels to evolve even further, expanding their reach and influence in the global market.

polyester fibre panel. This property is beneficial in energy-efficient building designs, reducing heating and cooling costs. Furthermore, their non-flammable nature adds an extra layer of safety, particularly in fire-sensitive areas.

The manufacturing process of polyester fibre panels involves a combination of compression and bonding techniques. Fibres are first spun and then bonded together to form a solid, dense panel. This process ensures that the panels remain lightweight yet robust, making them easy to handle and install.

Furthermore, polyester fibre panels are environmentally friendly. Many manufacturers utilise recycled polyester fibres, contributing to waste reduction and sustainability efforts. Their long lifespan and recyclability further enhance their eco-friendly credentials.

In conclusion, polyester fibre panels, with their blend of strength, resilience, and versatility, have carved a niche in numerous sectors. Whether it's construction for their durability, acoustics for their sound absorption, or energy efficiency for their insulation, these panels continue to demonstrate their worth. As technology advances, we can expect polyester fibre panels to evolve even further, expanding their reach and influence in the global market.

Additionally, polyester fibre panels offer thermal insulation, helping maintain consistent indoor temperatures

Additionally, polyester fibre panels offer thermal insulation, helping maintain consistent indoor temperatures

Additionally, polyester fibre panels offer thermal insulation, helping maintain consistent indoor temperatures

Additionally, polyester fibre panels offer thermal insulation, helping maintain consistent indoor temperatures polyester fibre panel. This property is beneficial in energy-efficient building designs, reducing heating and cooling costs. Furthermore, their non-flammable nature adds an extra layer of safety, particularly in fire-sensitive areas.

The manufacturing process of polyester fibre panels involves a combination of compression and bonding techniques. Fibres are first spun and then bonded together to form a solid, dense panel. This process ensures that the panels remain lightweight yet robust, making them easy to handle and install.

Furthermore, polyester fibre panels are environmentally friendly. Many manufacturers utilise recycled polyester fibres, contributing to waste reduction and sustainability efforts. Their long lifespan and recyclability further enhance their eco-friendly credentials.

In conclusion, polyester fibre panels, with their blend of strength, resilience, and versatility, have carved a niche in numerous sectors. Whether it's construction for their durability, acoustics for their sound absorption, or energy efficiency for their insulation, these panels continue to demonstrate their worth. As technology advances, we can expect polyester fibre panels to evolve even further, expanding their reach and influence in the global market.

polyester fibre panel. This property is beneficial in energy-efficient building designs, reducing heating and cooling costs. Furthermore, their non-flammable nature adds an extra layer of safety, particularly in fire-sensitive areas.

The manufacturing process of polyester fibre panels involves a combination of compression and bonding techniques. Fibres are first spun and then bonded together to form a solid, dense panel. This process ensures that the panels remain lightweight yet robust, making them easy to handle and install.

Furthermore, polyester fibre panels are environmentally friendly. Many manufacturers utilise recycled polyester fibres, contributing to waste reduction and sustainability efforts. Their long lifespan and recyclability further enhance their eco-friendly credentials.

In conclusion, polyester fibre panels, with their blend of strength, resilience, and versatility, have carved a niche in numerous sectors. Whether it's construction for their durability, acoustics for their sound absorption, or energy efficiency for their insulation, these panels continue to demonstrate their worth. As technology advances, we can expect polyester fibre panels to evolve even further, expanding their reach and influence in the global market. Latest news

-

Waterproof Dog Blankets for Indoor and Outdoor UseNewsAug.01,2025

-

Sustainable Wool Cat Beds Eco-Friendly Choices for Pet OwnersNewsAug.01,2025

-

Snuffle Ball Benefits for Dogs Mental Stimulation and ExerciseNewsAug.01,2025

-

Puppy Treat Puzzles as Social Tools Fostering Bonding Through PlayNewsAug.01,2025

-

Custom Wooden Pet Houses Tailored to Your Pet’s PersonalityNewsAug.01,2025

-

Corrosion Resistance in Environments: A Guide for Washer Hose ClampsNewsAug.01,2025